Services

| |

RPA offers a vast array of Design Engineering Services to help you take your ideas and transform them into, new products, improved products and efficient manufacturing processes to make those products. We understand and have many times taken the steps needed to move an idea forward and can help you make your ideas a reality.

| |

Plan the capital investments required to manufacture a product.

Develop new technology and

integrate existing technology into your facility.

Customer needs analysis

Moderate the technical side of customer meetings.

Manufacturing preliminary cost analysis

Product profit modeling and analysis

In-house brain storming sessions

Patent development & review

Product proto-type design, manage build and test.

Material selection & testing.

Product testing.

Regulator requirement analysis, implementation and documentation.

Formal systems for innovative idea management.

Manufacturing cost analysis.

Manufacturing method analysis.

Process change cost benefit modeling and analysis

In-house brain storming sessions.

Manufacturing process, proto-type, design, manage build and test.

Regulator requirement analysis and documentation.

Lean manufacturing systems & methodology.

Flow diagrams, work Instruction & procedures as per ISO Standards.

Sourcing and acquisition of manufacturing equipment with commissioning.

Verify if the process idea is theoretically, physically, technically and fiscally feasible and will delivery the returns anticipated.

Toll manufacturing, sourcing and qualifying.

Quality system design.

We have experience with processes that have multivariable inputs in continuous stream type manufacturing. Example: Printing, coating, mixing, drying etc.

Feasibility studies to verify if the process idea is, theoretically, physically, technically and fiscally feasible and will delivery the results anticipated.

Proof of concept via design, manage build and testing of process prototypes.

Manage the design and building of new processes.

Isolation of critical process variables.

Optimizing process variables using statistical methods. (Finding the Sweet spot)

Process functionality investigation, determination and documentation.

Trouble shooting process issues.

Investigate interactions between materials.

We have experience managing international development projects worth up to $4 million.

Develop and manage project plan.

Develop requests for quote.

Establish design, manage build and install teams and facilitate communication.

Select and manage technical & trade resources.

Track the progress, costs and provide regular reports.

Oversee the design of new products, processes, and equipment.

Oversee the installation of new technology and equipment.

Assist with your products qualifications at your customer's facility.

Regulator requirement analysis, implementation and documentation.

Toll manufacturing, sourcing and qualifying.

From basic mechanical jigs & fixtures, to integrating new technology with existing equipment in your plant or designing entire processing lines, we can help you with all your machine design needs.

Detailed design & drafting with 3D models. (SolidWorks™)

Stress analysis

Strength of materials.

Dynamic analysis with modeling.

Linear & rotary motion control. (Robotics)

PID thermal control.

Operator interfaces.

Component/material use & selection.

We have experience designing and managing the development of speciality manufacturing equipment.

Develop equipment specifications.

Develop requests for quote with review and reward process.

Qualification of equipment prior to possession.

Manufacturing equipment proto-type, design, manage build and test.

Integration of equipment/technology into one machine or processing line.

Regulator requirement analysis, implementation and documentation.

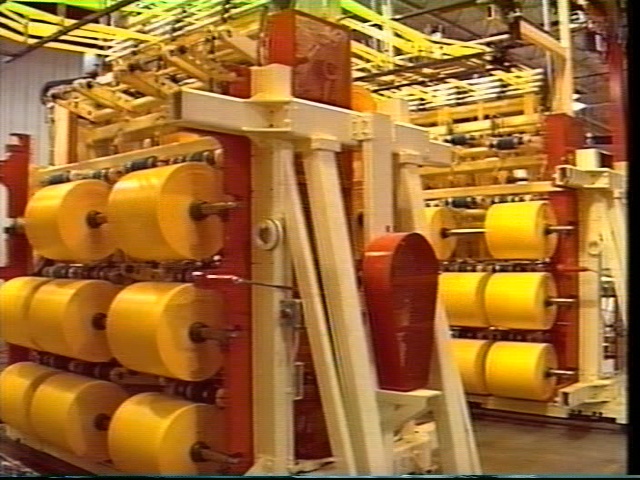

We have over 25 years experience and expertise in the processing of material in web form.

Printing Coating & Drying. Silicone release, hot melt, acrylic & rubber PS adhesives, gravure printing & coating, slot-dye and spay nozzle.

Slitting. Shear, score, razor, water-jet and high speed rotary.

Tape Packaging. Pancake roll winding, spool winding and festooning.

Converting Equipment Design & Modification. Machine design, drying ovens, heat transfer rolls, pay-offs, take-ups, integrate control and mechanical systems, ergonomics.

Web guiding and handling. Nips, air-bars, guiding, turning bars, idler rollers, tension controls, phase lock systems, automatic splicing, thermal splicing.

Roll handling. Core chucks, down enders and clamp trucks.

Laminating & Sealing. Coloured & clear substrates, hot & cold process rolls, dry adhesive laminating, ultra-sonic welding, materials: paper, plastic, metal foil and heat sealable films.

Folders.

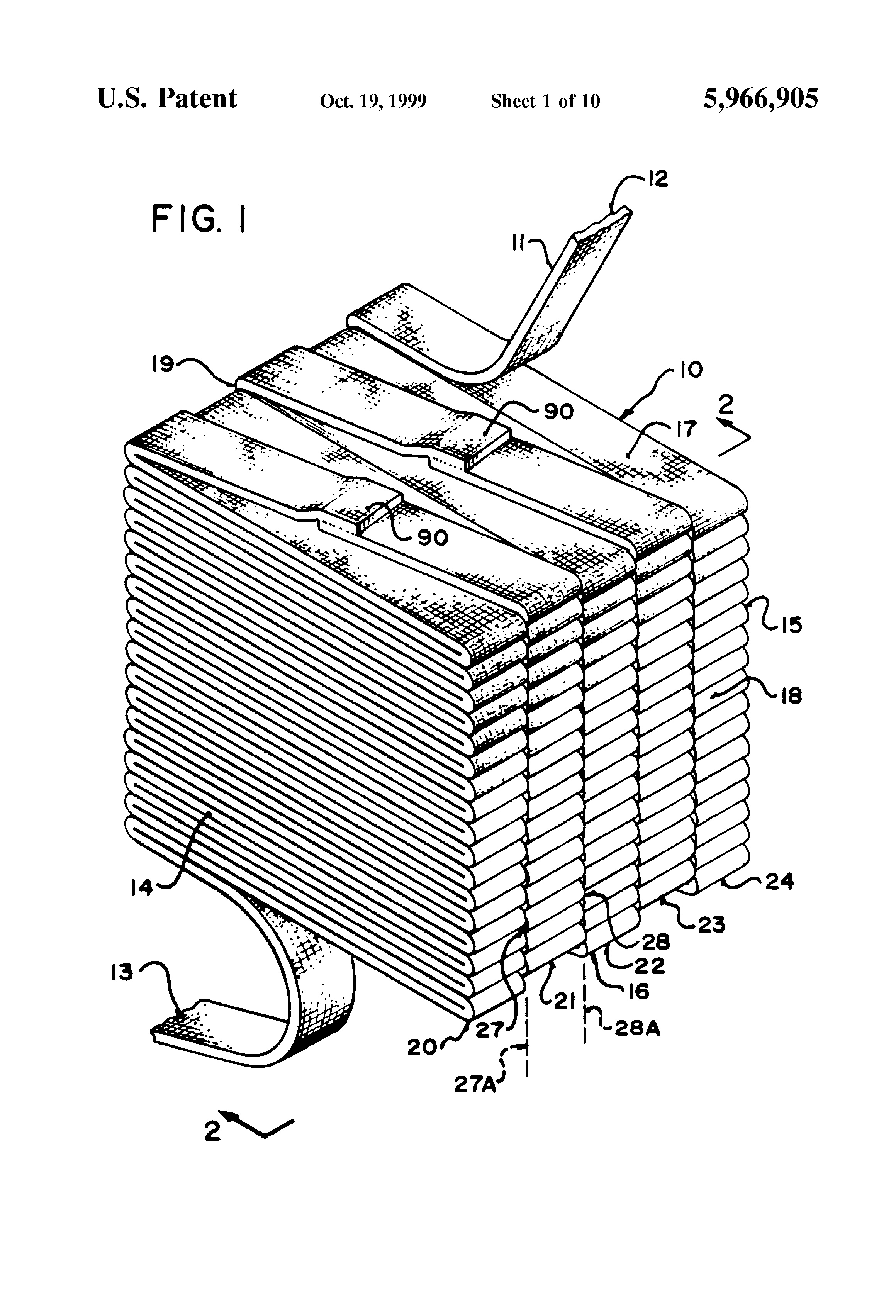

When it's time to develop a patent for your product, process or machine, we have the experience deciphering your process and preparing the data and documentation required by your Patent Attorney to search prior art and write up your patent. We also can help with review of the patent before submittal, making sure all the details are covered.

Investigating prior art

Providing sketches and illustrations.

Innovating around existing Intellectual Property road blocks and prior art.